Add products by adding codes

Practical Applications of Full Metal Inductive Sensors

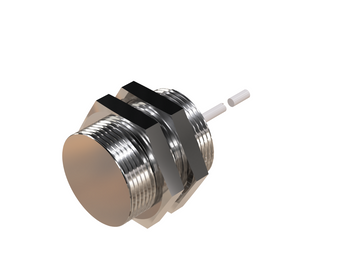

Full Metal Inductive Sensors are advanced solutions that ensure reliability even in the most demanding conditions. Their exceptional durability and resistance to damage make them widely used in industries where precision and strength are crucial. Thanks to their robust construction, they perform excellently in extreme environments, playing an indispensable role in many industrial processes.

Challenges in the Welding Industry

In the world of welding, where extreme temperatures prevail and the air is filled with welding dust, full metal inductive sensors become indispensable tools. Thanks to their resistance to high temperatures and harmful external factors, they perform exceptionally well even in the toughest conditions. They precisely detect metal elements, enabling the automation of the welding process and ensuring accurate quality control. These sensors act like silent guardians, making sure that every weld is perfect and the entire process runs smoothly.

Reliability in Metalworking

In metalworking plants, where machines are subjected to massive loads every day and surfaces experience constant vibrations and shocks, full metal inductive sensors become the foundation of reliable production. Their solid metal housing not only protects them from mechanical damage but also ensures longevity when in contact with cutting tools or lathes.

Automation and Control of Production Processes

In a world where every minute of downtime costs money and precision is crucial, full metal inductive sensors step in to take control over every stage of production. From assembly lines in the automotive industry to food factories and electrical manufacturing plants — these sensors ensure uninterrupted operation and perfect metal object detection at every phase of the process. With their help, processes become more efficient, and downtimes are minimized to an absolute minimum. Thanks to their reliability, they become an indispensable part of production automation, ensuring everything runs like clockwork.

Full Metal Sensors – A Trustworthy Choice

Choosing the right sensors for special tasks is crucial for the efficiency and safety of production processes. Among the manufacturers delivering top-quality solutions in this field, Nexotec stands out. We offer full metal inductive sensors that combine high-quality workmanship, innovation, and reliability in the toughest industrial conditions. Full metal inductive sensors from Nexotec are the ideal solution for companies looking for durable, damage-resistant, and precise devices for monitoring production processes. The use of our sensors in demanding applications translates into improved efficiency and safety, as well as reduced downtime and repair costs. Thanks to attention to every detail and continuous technological improvements, at Nexotec we focus on quality that meets the expectations of even the most demanding industries.

Summary

Full metal inductive sensors are a key element of automation in many industries that require precise detection of metal objects in harsh conditions. Their resistance to mechanical damage, corrosion, and high temperatures makes them perfect for welding, metalworking, and automation of production processes. Thanks to their reliability and longevity, they ensure high efficiency in demanding industrial applications.