Add products by adding codes

Add a CSV file

Enter the product codes that you want to add to the cart in bulk (after a comma, with a space or from a new line).

Repeating the code many times will add this item as many times as it appears.

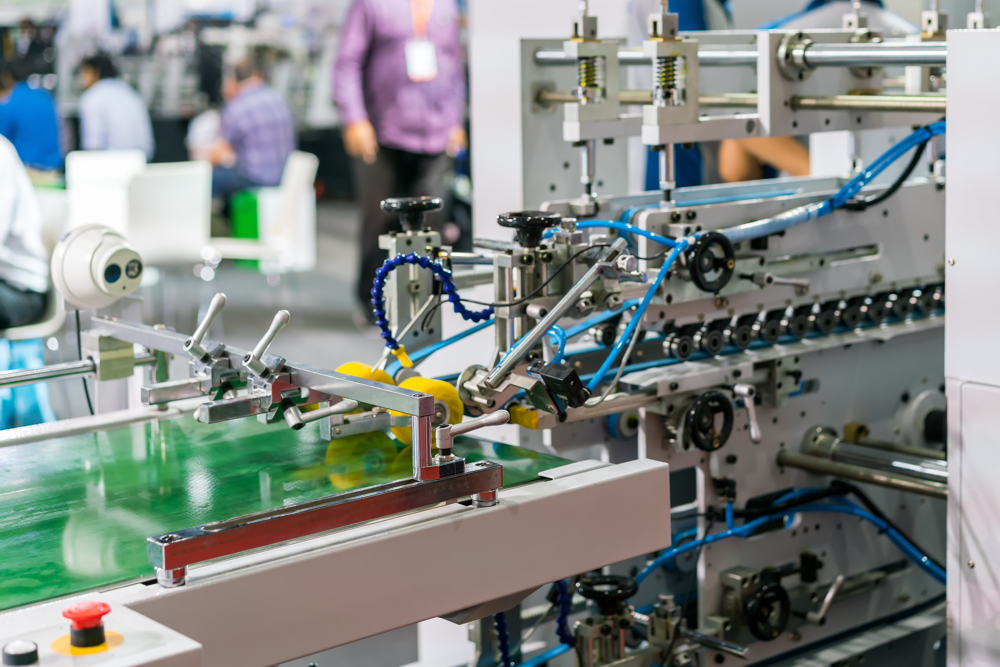

Inductive sensors with a fully metal face are used in many demanding industrial applications where standard sensors may not withstand harsh conditions. Here are some examples of applications:

Automotive Industry:

- Detecting the position of mechanical parts in assembly systems.

- Monitoring production lines where sensors are exposed to oils, greases, and other chemicals.

Metallurgical Industry:

- Monitoring the position and movement of metal components in metalworking processes such as milling, turning, and stamping.

- Detecting objects in harsh conditions, such as high temperatures and the presence of metal shavings.

Food and Beverage Industry:

- Applications requiring high hygiene standards, where sensors must withstand frequent washing, detergents, and other cleaning agents.

- Monitoring packaging and food processing operations.

Chemical and Pharmaceutical Industry:

- Applications in explosion-hazard zones, where sensors must be resistant to corrosion and aggressive chemicals.

- Monitoring pharmaceutical and chemical production processes, requiring high resistance to chemical agents.

Heavy Industry:

- Monitoring machines and equipment in harsh environments, such as mines, quarries, cement plants, and steel mills.

- Applications where sensors are exposed to vibrations, impacts, and dust.

Industrial Automation:

- Detecting the position and movement of components in automation systems where high reliability and durability are essential.

- Monitoring processes in harsh environments, where sensors must withstand extreme operating conditions.

Construction and Agricultural Machinery:

- Monitoring and controlling the position of moving machine parts operating outdoors in challenging weather conditions.

- Applications requiring resistance to mud, dust, water, and other external factors.